For Baking Trials...

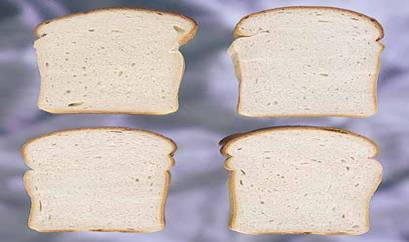

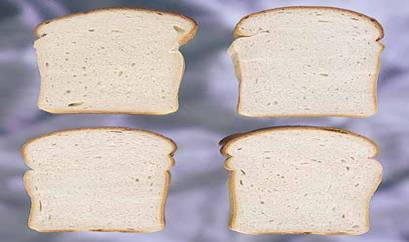

Figure 1 shows the effects of different pentosanase enzymes.

Top left is the control loaf and contains no additive.

Top right is the loaf with Trichoderma sp. xylanase

– note the uniform structure.

Bottom left was produced using Bacillus sp.xylanase

giving an open structure.

Bottom right is the loaf with Aspergillus enzyme xylanase, which

is ideally suited in no-time fermentation systems and gives good volume and

height increases.

In addition to the development of

new products have been further evaluated to determine how effective they are in

the production of a standard white loaf. Once the bakes were complete the

products were analysed for their crumb structure, colour, texture, taste and

physical parameters such as loaf height and oven spring.The new information from

these trials, not just about the finished product, but also with regard to the

ease of processing of the dough. This is exemplified by the xylanase story.

We’ll examine a wide range of baking xylanase enzymes in here. It is known that

the performance of the different types of xylanase enzyme is highly dependent on

the process it is used in. In addition the effect of other enzymes on the dough

is greatly impacted by the type of xylanase enzyme used. The Bacillus sp. enzyme,

gave a soft, workable dough which was easily machined and gave rise to a loaf

with an open structure, typical of a European type bread. The Aspergillus enzyme,

gave rise to a strong dough, which was easy to machine and produced a loaf with

a tighter crumb and a uniform texture. The strength of the dough produced by

Aspergillus enzyme suggests that this enzyme would be particularly suited for

use in longer fermentation processes, and particularly for overnight

fermentations where excessive dough softening can be a problem. The third enzyme,the

Trichoderma sp. Xylanase, gave rise to a much softer, silkier dough which is

exactly that required in no-time fermentation processes and the Chorleywood

process.

Glucose Oxidase enzymes for industries other than baking, and that was all

trialled as baking additives. The success of the baking Glucose Oxidase,to

providing the industry with standardised products for optimal activity and act

in the early stages of the process, before oxygen becomes limiting. The end

result is a product that has a very soft texture over an extended period

preserving.